- 翰林提供学术活动、国际课程、科研项目一站式留学背景提升服务!

- 400 888 0080

CIE A Level Biology复习笔记3.2.8 Enzyme Activity: Immobilised v Free

Enzyme Activity: Immobilised v Free

- Enzymes can be added to solutions and are thereby considered ‘free’ or they can be immobilised

- Immobilised enzymes are enzymes that have been bound to an inert, stationary and insoluble material such as alginate

- The substrate is then passed over the immobilised enzyme and the product is collected

- Advantages to this method:

- There is no enzyme in the product (the product is uncontaminated) and therefore there is no need to further process or filter the end product

- The immobilised enzyme can be reused multiple times which is both efficient and cost-effective (enzymes are expensive)

- Immobilised enzymes have a greater tolerance of temperature and pH changes (immobilisation often makes enzymes more stable)

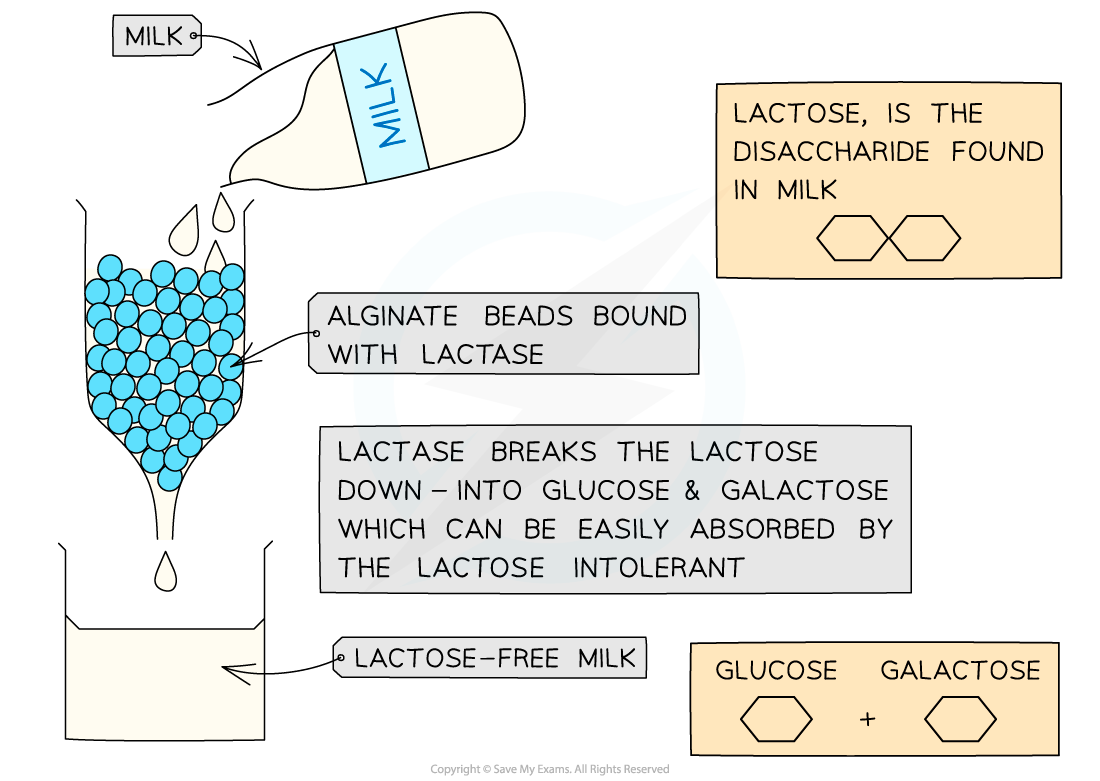

- A practical application of immobilised enzymes used in the food industry is in the production of lactose-free milk:

- Milk is a valuable source of nutrients containing protein, fat and the carbohydrate Lactose

- 5-10% of the UK population are lactose intolerant

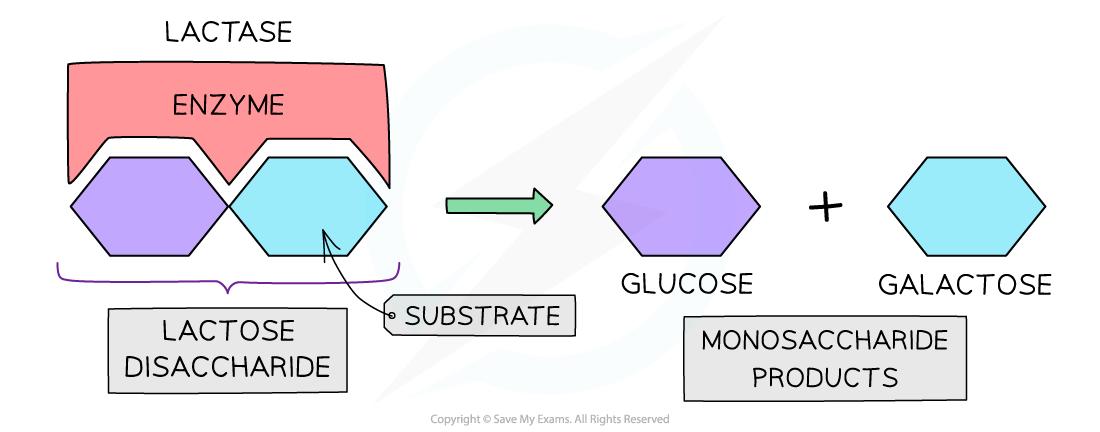

- Lactose is a disaccharide that is broken down into glucose and galactose

Using immobilised enzyme to modify milk

- Using lactase as shown above is an efficient way to remove lactose from milk and to provide lactose intolerant individuals with a way of consuming milk without suffering intolerance symptoms:

- The enzyme lactase can be immobilised using alginate beads

- Milk is run through the column of lactase-containing beads

- The lactase hydrolyses the lactose in the milk to glucose and galactose

- This ensures the milk is lactose-free

- It can also then be used to make other lactose-free dairy products

Lactose is a disaccharide that is broken down by lactase into the monosaccharides glucose and galactose

转载自savemyexams

最新发布

© 2026. All Rights Reserved. 沪ICP备2023009024号-1